Welcome to our third Aquamax Update

In this edition we focus on water jetting applications for concrete – hydrodemolition, scabbling and stencilling.

Reducing Structure-Borne Noise with Hydrodemolition

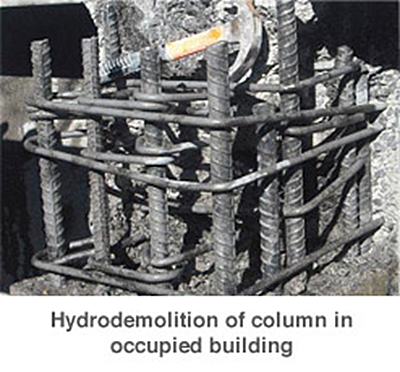

We have been involved in two projects recently – both office towers undergoing seismic upgrades. These buildings have been fully occupied and structure-borne noise has been a real problem for the contractor. Aquamax has been engaged using water jetting as an alternative to mechanical breakers for removing concrete around the steel structure. The water jetting process does not directly impact the structure, does not damage the steel and significantly reduces construction related noise heard through the building. We have utilised our low flow rate pumps to minimise mess when working on upper floors.

Scabbling

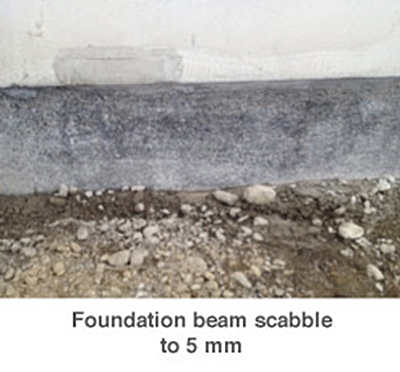

We are utilising our medium flow rate pumps where there are significant quantities of concrete for hydrodemolition and scabbling work both on new builds, seismic strengthening projects, and general infrastructure repair work. These pumps are now equipped with twin guns to maximise productivity for scabbling large areas. Water jetting is a great alternative to mechanical scabbling. Being a wet process, dust is kept to a minimum and the scabbled finish is very stable and dust free. More details.

Stencilling

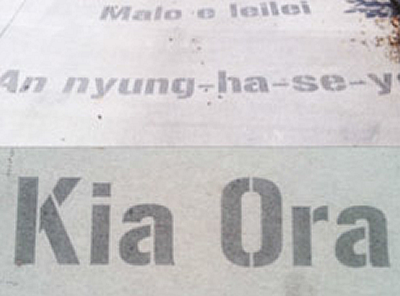

Our process is capable of exposing aggregate on hardened concrete. By utilising a custom-made steel stencil, we can create innovative effects such as greetings or artistic patterns to add value to what might otherwise be a plain concrete surface.

More details

Please do not hesitate to get in touch if you have any questions about these applications. Contact Us

Wishing you a relaxing Easter break,

Regards,

Hamish Coop – CEO

021 316 844